Before we can take a bite of a juicy sandwich, each and every ingredient has been through its own journey of production, screening, packaging, storage, distribution and preparation. There is potential for innovation throughout the value chain. Nordisk Industrifond (now Nordic Innovation) saw this potential and decided to develop the NorFood program.

Food focus

NorFood kicked off in 1993, after a decision by the Nordic Council of Ministers to make the food industry one of four priorities in their strategy. The official goal of NorFood was to “contribute to ensuring the food industry's competitiveness in the changed market by achieving critical mass in selected research areas.” The selected research areas were packaging, food quality, food hygiene, and new methods/processes.

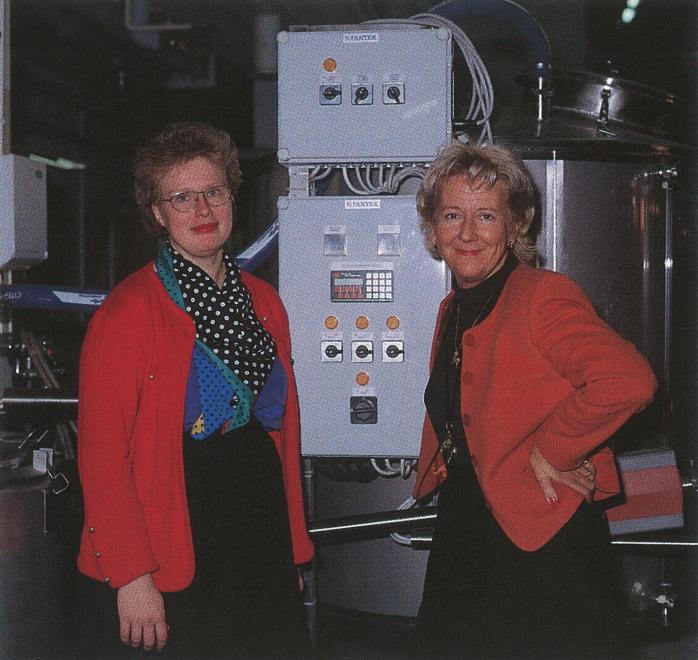

Two projects with a duration of four years were launched with a budget of 300 million NOK. Nordisk Industrifond contributed 30 per cent of this budget. Around 200 companies, 30 research institutes and 14 universities partook in the projects.

By 1995, more than 100 publications under NorFood had been published. Seminars and conferences had also been initiated at this point to share the research findings.

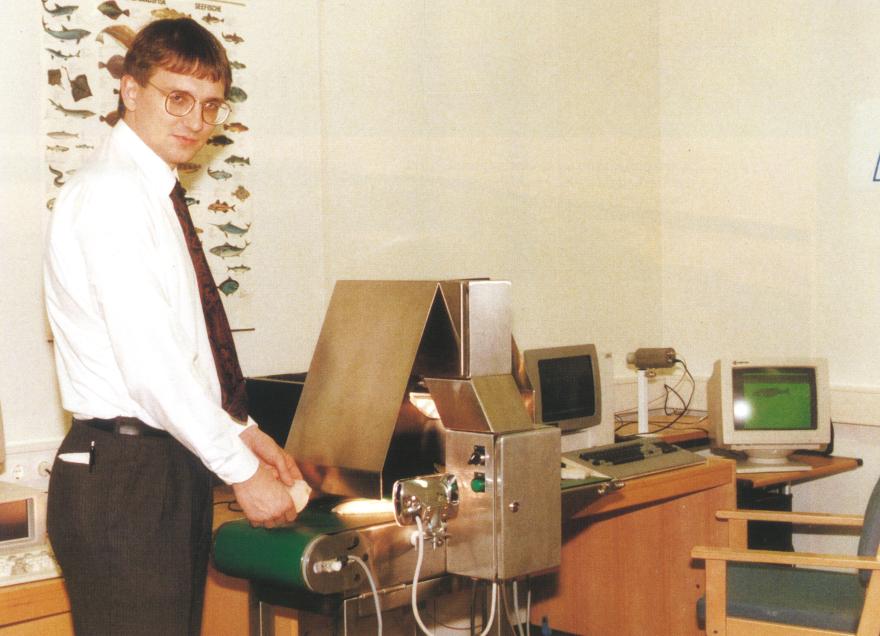

Waterjet Deboning (WJD)

How can we ensure that meat and fish processing become smarter? One key research in the NorFood initiative investigated how water can be used to fillet fish. The invention of waterjet knives meant that the process of filleting fish became increasingly efficient, and it also led to a reduction in production costs. Consequently, it has had benefits for consumers as well, as this initiative has contributed to lowering the cost of meat and fish.

The Waterjet Deboning project brought industry, institutions, and academia together, bridging four Nordic countries, five companies and one university together to optimize fish mince. As such, the project shares information between academia and industry as well as fueling Nordic cooperation on innovation in the fish and meat processing industry.

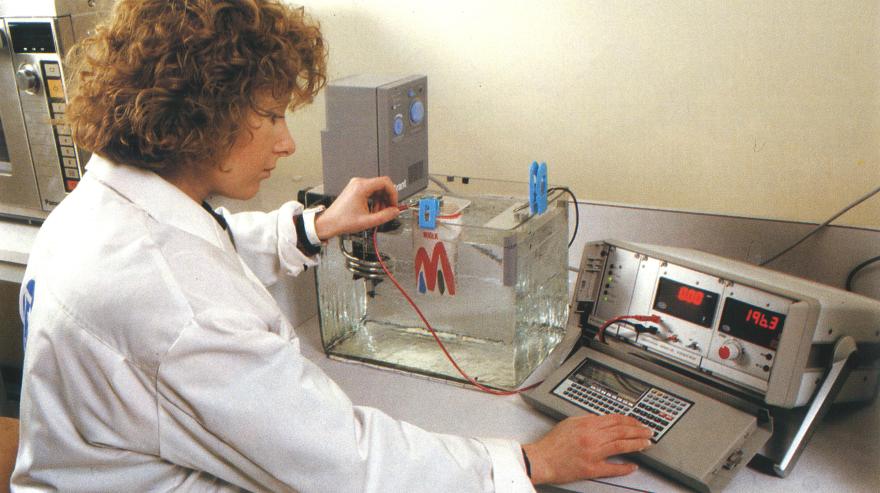

High pressure processing

In 1994, the Nordic countries begun studying the effect of high-pressure processing for the durability of food. Research on the field had already blossomed in the US, Japan and England at this time – and in 1994 the Nordics were eager to investigate the effect on microorganisms and enzymes.

In the infancy of the project, collecting literature was key to understanding the existing frameworks of the research. The Nordic research community travelled to Japan which later resulted in two seminars completed in 1994.

Futureproof food

Another project focused on improving grain in foods. Hydrothermal treatment of grain proved highly effective in enhancing a series of benefits for foods. By combining heat and water grain became even healthier – and with longer durability. Hydrothermal treatment combined traditional methods of grain processing and modern malting processes. The result? The nutrient value was enhanced, durability was extended and even the flavor was affected throughout the process.

Reaching beyond the Nordics

By the end of the 90s, NorFood had caught the attention of the continent. EU stated that the project had reached new heights in terms of food research. As a result, the project was integrated into the EU, a decision largely influenced by Finland, Sweden and Denmark’s EU membership.

What started as a project to secure the interest of consumers, later became the very foundation for the Nordic venture on food security. NorFood representatives travelled across 18 EU members states to establish contact with the different research communities as well as central decision makers. The work has been dubbed a translation project and was concluded in 2004.

Lasting impact

The NorFood program ended up running as two four-year programs, as the topics included in the program were of high interest among both companies and researchers. About 40 R&D projects were part of the program, and the program included 200 companies, 30 research institutions and 14 universities. Approximately 600 individuals were actively involved in the work of the program.

Although the NorFood project ended in the 00s, the production methods and insight from many of the projects are still in use today. Since the 90s, Nordic Innovation has continued with different projects concerning food, especially within the marine industry. Sustainable ocean economy is one of the current programs, where the exploration of new opportunities in ocean food is a major component. The NorFood project also created a foundation for continuous Nordic cooperation between the national food agencies, independently of projects run by Nordic Innovation. A good example is a recent report calling for a Nordic approach to food safety risk management of seaweed for use as food. The report was written in collaboration between the different Nordic food agencies.

The Nordic food industry has developed into a dynamic and thriving sector that showcases a unique blend of tradition, innovation, and sustainability. During the past decade the industry has increasingly embraced a forward-thinking approach by placing a strong emphasis on sustainability, with initiatives such as reducing food waste, promoting local and seasonal produce, and incorporating plant-based alternatives. This commitment to sustainable practices has not only resonated with consumers but has also positioned the Nordic food industry as a global leader in responsible and ethical food production.

Facts:

- NorFood 1 ran from 1993-1997 with a focus on packaging, food quality, food hygiene, and new methods/processes

- Norfood 2 ran from 1998-2001, with a focus on processes (safety, hygiene, health, information technology and logistics), market challenges (consumer trends, market structures, globalization) and information (communication and knowledge transfer from researchers to the industry)

- The NorFood project model, including the focus areas, was adopted on an EU scale in the beginning of the 2000s. The launch of this EU-project was heavily aided by NorFood representatives

NorFood 1 and 2 key numbers:

- 40 R&D projects

- 200 participating companies

- 30 research institutions

- 14 universities

- 600 individual, active participants